CÔNG TY TNHH THƯƠNG MẠI VÀ DỊCH VỤ CƠ KHÍ HOÀN THIỆN

CÔNG TY TNHH THƯƠNG MẠI VÀ DỊCH VỤ CƠ KHÍ HOÀN THIỆN

CÔNG TY TNHH TM - DV CƠ KHÍ HOÀN THIỆN

Địa chỉ: 36/34,Nguyễn Gia Trí, Phường 25, Quận Bình Thạnh., TP Hồ Chí Minh

Tel: +028-62587684~6 - Fax: +028-62587687 Email: htcl@hoanthien-tools.com.vn

Hỗ trợ kĩ thuật: Tungaloy Vietnam (LE 04-38, Lexington Residence , 67 Mai Chí Thọ, Phường An Phú, Quận 2, TP. HCM)

Tel: +028-37406660 Fax: +028-37406662 Email: info@tungaloy.vn

Danh mục sản phẩm

Trang chủTin tức & sự kiệnPress releaseExchangeable head tooling solutions

Trang chủTin tức & sự kiệnPress releaseExchangeable head tooling solutions

Exchangeable head tooling solutions

Cutting tools have evolved from a brazed tool to a mechanically clamped indexable tool and now a replaceable tool. Tungaloy is at the forefront of evaluating new concepts and ideas for more productive tools and developing these solutions for overall improvements for our customers. Through this article, we share Tungaloy’s unique exchangeable head solutions for milling, drilling and reaming operations.

The modular concept is not new. In fact, childhood games such as the jigsaw puzzle follows this concept to bring a preconceived idea into a shape.

And, building blocks are actually an exchangeable block type toy which began an engineering aptitude for many. Tungaloy’s exchangeable head tooling solutions are an adaptation of this idea and helps in building multiple useful tool assemblies. With just about 50 odd blocks, we created hundreds of logical shapes. We built cars, trucks, buses – Automotive, we built aeroplanes and other flying objects – Aerospace, Trains – Railway, houses, bridges – Infrastructure, simple machineries – Equipment’s and general engineering

Tungaloy has emerged as a leading metal cutting solution provider, with exchangeable head tools, for building stronger Automotive, Aerospace, Equipment and general engineering, infrastructure and railway industries.

What makes exchangeable head or modular head tool a better option to our customers?

An exchangeable head tool is designed as a cutting head and a holder with precise connection between the two. This offers multiple advantage to customers.

- Flexibility: The tool body is made from high-quality steel, which is more flexible compared to solid carbide. Hence, it can be used at optimum parameters, even under adverse conditions and unusual application such as uneven entry & exits or not so rigid fixture setup. A solid carbide tool would tend to chip or break in adverse conditions or when applied at high productive parameters.

- Reduced non-productive time – An exchangeable head equals ease of indexing. With a conventional end mill, reamer or drill the tool must be taken out of the machine, be replaced with a reground or new tool, and then put it back in the machine. This process adds to a lot of non-productive time or simply put – wasted time. With an exchangeable head tool, it is indexed right on the machine saving time thus increasing productivity.

- Best R.O.I – Cost of a solid carbide tool is very expensive compared to an exchangeable head solid carbide tool. Every single recondition of the tool costs about 1/10th of the original tool cost but does not guarantee original tool performance. In addition, it also requires time consuming overhang setup. Head exchangeable tools are not regrindable and have a constant overhang. Hence, exchangeable head tools, offer the best ROI.

- Excellent process control – With no regrinding and no frequent offset input, exchangeable head tools offer excellent process control as it uses a fresh cutting edge every time. Due to the manual intervention of a reground tool, there is always possibility of error.

The tool diameter and length of a solid carbide tool keeps changing after every regrind. Hence, careful monitoring is necessary.

With Tungaloy’s exchangeable head tool, it’s a non-issue.

- Safety – With no manual intervention, there is the least chance of an accident related to the tools.

- Lower inventory – When using Solid carbide tools, customer must keep a minimum of 3-4 tools to run the production cycle, without the risk of running out of tools. With exchangeable head tools, a minimum inventory of heads is required.

Tungaloy takes care of safety stock for customer thus lowering the customer’s expenses.

One exchangeable head can be used on drill bodies of different length, with Tungaloy’s DrillMeister

- Build tools to need – Just like building blocks, we can create a tool assembly in the required diameter and length with modular tooling systems well within the principles of tool design.

TungModular blade system enables customer to build different tool assemblies for different grooving applications – shallow grooving, deep grooving, face grooving, groove turn system etc.

The first row of Tungaloy’s deep shoulder mill (TungTri TLA) is an exchangeable ring which enables customers to build longer tool assemblies based on their requirement.

- Reliable performance – No regrinding means no faulty angles on the tool. Hence, performance repeats every time customer uses Tungaloy’s exchangeable head tool with 100% reliability.

- Helping Go Green – Every exchangeable head tool requires less tool material, the rest of it being tool steel body. Therefore, compared to a full solid carbide tool, it leaves a lower carbon footprint. With an increased usage of Tungaloy’s exchangeable head tools, lower energy consumption and customers would be helping in creating a greener planet for our future.

Exchangeable head tooling solutions from Tungaloy:

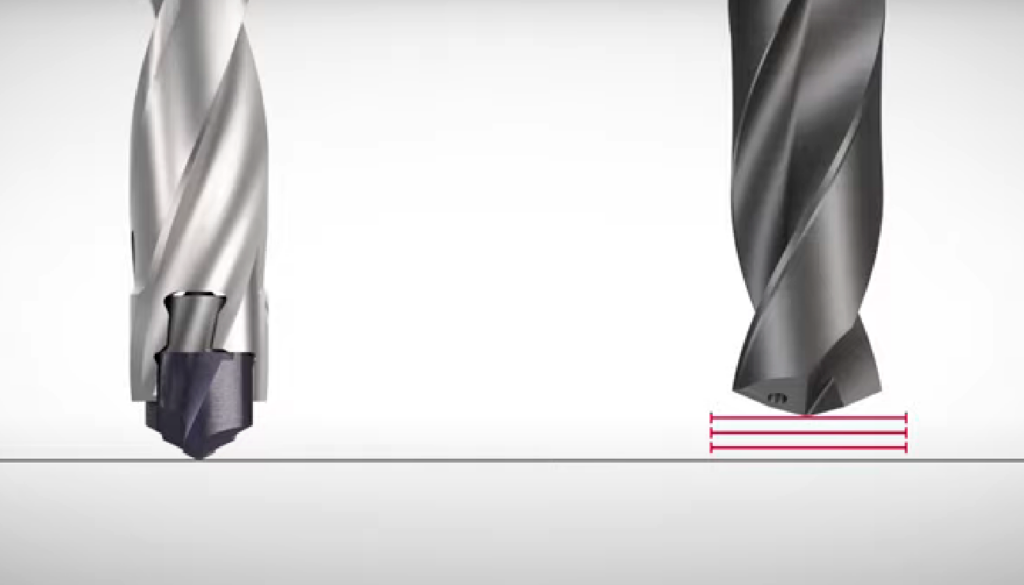

Tungaloy’s DrillMeister, offering a unique self-clamping drilling head, TungMeister with threaded connection and ReamMeister with tapered screw expansion clamping, have introduced revolutionary changes in exchangeable tooling solution.

One of the greatest advantages with exchangeable heads is that they can be offered in a wide range of grades, unlike the solid carbide tools, which are normally produced from a K10F grade. Tungaloy offers AH715 / AH725 / AH735 and AH750 grades in its TungMeister range and with just one shank, customer can perform roughing, finishing, high feed, ball finish or even trochoidal operations, using various type of heads. Selection of head would be based on the machine condition and the machining process, thus defined – low depth, high feeds, low width of cuts and high depth of cuts etc. Over 13,000 tool combinations possible with TungMeister.

Wide range of geometries

45 kinds of are available. The head indexing is easy and highly accurate with precision thread

Three kinds of shank material

Steel: for general purpose

Carbide: for highly accurate machining due to excellent rigidity

Tungsten: reduced chattering due to high vibration damping capacity

Similarly, DrillMeister offers 50 drilling possibilities per drill body. The clamping of the drill head is so unique, it offers the most reliable clamping, retaining the elasticity of the body and offering extended tool body life.

- DMP geometry for general drilling

- DMC for long overhang drilling

- DMF for flat bottom drilling

- DMH for heavy duty drilling

- DMN for aluminium alloy drilling.

Over and above this, special heads are also available for improved performance.

ReamMeister offers an innovative clamping mechanism to control runout and improve repeatability while maintaining IT7 hole accuracy and superior surface finish in parallel to high productivity.

The body accommodates a wide range of diameters with two types of heads – one for through holes (BL type) and the other for blind holes (AS type), so that it can effectively evacuate chips during the reaming process.

Thông tin khác

- Một bước đột phá với việc thiết lập công cụ bên ngoài máy dành cho máy tiện Thụy Sĩ cải thiện đáng kể năng suất

- Nâng cao độ chính xác trong gia công máy tiện tự động: Giới thiệu cải tiến SH7025

- TinyMiniTurn Offers CBN-tipped Boring Bars for Hard Part Machining

- Tungaloy Expands DoMultiRec’s Multifunctional Machining Capability

- AddInternalCut to Include Grooving Inserts for Industry-Standard Circlip Groove Profiles from 0.5 mm

- The AH8000 Series of Turning Inserts Offers SDM Chipbreaker for Longer Tool Life in Heat-Resistant Superalloys

- Tungaloy’s DrillMeister Offers Chamfering Holders for Small Diameter Holes